DEODORIZATION SYSTEM

Our deodorization system operates in two phases:

• First phase: Pre-heating treatment of the material.

• Second phase: The material is sent to a reactor that extracts the present contaminants.

The material exiting the extruder enters our drying/heating hopper [first phase], where it remains for a variable period depending on the amount of contaminants present. Once the treatment is completed, the material is automatically sent to storage. If a longer retention time is required, it is transferred to the reactor [second phase] to complete the process.

Inside the reactor [second phase], the material remains for a specific time based on the contaminants to be removed.

At the end of the second phase, the material is discharged and sent to the storage containers.

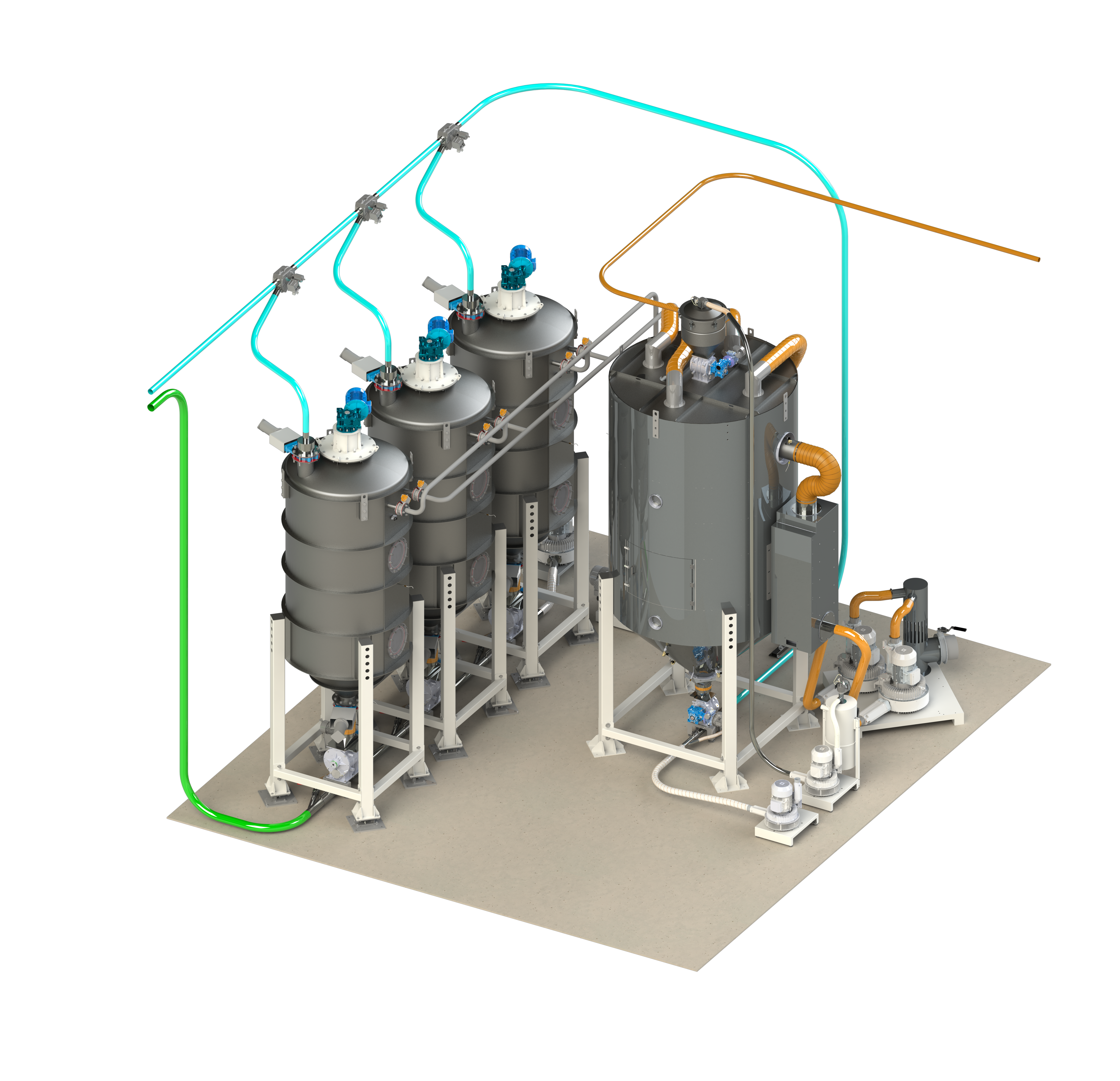

CENTRALIZED PLANTS

Centralized feeding and/or drying system is always tailor-made on client needs. Vacuum blowers are components that must be chosen, Vacuum blowers’ selection among side-channel, claw and Roots types with different powers and vacuum levels. Vacuum blowers are always provided with filtration devices with different filtering capacity according to requested potentialities. n case of pressure feeding, compressors can be: side-channels or Roots type, and in case of dense phase feeding, compressors are equipped with pressurized thrusters.

Material receivers could be for granules, flakes or powder, with different volumes, sizing from 2 to 200 litters as standard, up to 2000 litres for special applications with suitable filtering systems. Material unloading can be: tilting clapet, with pneumatic butterfly valve, rotary valve or free valve for cyclone systems.

Regarding materials selection and their traceability, can be used automatic control unit with Cartesian axis movement matrix plates for the solution for granules, they guarantee an Industry 4.0 management of traceability, together with PLC TOUCH SYS EVO control system and our process SCADA supervision system.

Our centralized systems are used for injection, extrusion, blowing, rubber production, compound and in PVC lines.